3D Printer Consumables

Check out our wide range of consumables from filaments for FDM printing to resins for SLA printing. We offer fantastic pricing on leading brands such as Formfutura, Formlabs, Ultimaker, and Dremel.

FormFutura Consumables are now 10% - 40% cheaper. Plus discounts available on other brands.

Hurry and stock up today!

Form 2 Rigid Resin

Rigid Resin is glass filled resin offering a very high level of stiffness and a ultra-smooth finish. It’s highly resistant to deformation over time and is perfect for thin walls and features.

Call for pricing

Form 2 Tough Resin

Formlabs Tough Resin was designed to simulate ABS plastic, with comparable tensile strength and modulus. Perfect for functional prototyping, this sturdy, shatter-resistant material has been developed to withstand high stress and strain.

Call for pricing

Formlabs Draft Resin Cartridge

This Draft Resin version is a legacy formulation of Formlabs current Draft Resin.

The latest formulation prints up to 4 times quicker compared to Standard Resins. It offers numerous improvements such as improved surface finish, easier to use and a more professional appearance.

Call for pricing

Form 2 Durable Resin

Durable was designed to simulate polypropylene (PP) plastic, with comparable low modulus and high-impact strength. Use this wear-resistant, ductile material when parts require deformation and a smooth, glossy finish.

Call for pricing

Form 2 High Temperature Resin

High Temp has an HDT of 238 °C @ 0.45 MPa—the highest of the Formlabs 3D printing materials. This material is great for static applications that will undergo higher temperatures. High Temp can also be used for production processes such as casting and thermoforming.

Call for pricing

Form 2 Flexible Resin

Flexible simulates an 80A durometer rubber. Use this versatile material to produce parts that need to bend and compress. Flexible is excellent for simulating soft-touch materials and adding ergonomic features to multi-material assemblies.

Call for pricing

Form 2 Castable Wax Resin

Delicate Geometries, High Precision and Accuracy: Castable Wax is recommended for filigree, pavé, and pieces with ornate surface detail with no visible layer lines.

PRE-ORDER

PRE-ORDER

Call for pricing

Form 2 Grey Pro Resin

High precision, deformation resistant, Grey Pro Resin makes a versatile material perfect for a wide range of engineering applications.

Call for pricing

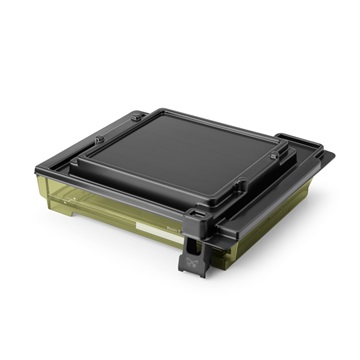

Form 2 Resin Tank

Formlabs Resin Tray blocks light and is made from shatter-resistant polycarbonate. It comes with a reusable lid and wiper, making it easy to stack tanks and store resin outside of the machine.

Call for pricing

Form 3 Resin Tank

The Form 3 resin tank is the main vessel for holding the resin when it is dispensed from the Formlabs resin cartridge. Resin is cured onto the flexible build layer, the laser passes through the tank's bottom film.

Call for pricing

Form 3L Resin Tank

Low Force Stereolithography (LFS) 3D printing uses linear illumination and a flexible film tank to turn liquid resin into flawless parts. A key component of the LFS process, the strong dual-layer film at the bottom of the Form 3L Resin Tank allows for a dynamic and precise print process, scaled up for large format printing.

Call for pricing

Form 2 Resin Tank LT

Resin Tank LT is suited for long term use and rigorous, high volume printing, with a 2 to 5x longer lifetime depending on the material, more accurate printer detection, anti-spill geometry, and easier wiper release for streamlined workflows.

Call for pricing

Form 2 Colour Resin Kit

The Form 2 Colour Kit comes with a cartridge of base colour and all 5 Colour Pigments. Mix and print opaque and matte parts in a range of colours.

Call for pricing

Form 2 Colour Pigments

Using Color Kit, anyone can mix their own Color Resin and create uniformly colored 3D prints with the high resolution and smooth surface finish SLA technology is known for.

The Formlabs Color Kit is part of the Standard Resins lineup. General purpose materials for the Form 2, perfect for rapid prototyping and concept model. Product designers, engineers, prop designers, and professionals enjoy these materials for their high detail, surface finish, and minimum finishing.

Call for pricing

Formlabs Form 2/3 Build Platform

A spare Formlabs Build Platform can speed up your workflow, whether you're changing resins or starting a new print while you remove your part.

Call for pricing

Filter by:

Clear All