Formlabs

Formlabs offers SLA desktop 3D printers that are affordable and easy to use. Formlabs high-resolution 3D printers produce high-quality and highly detailed prints that are much better than that of plastic extrusion printers. Formlabs started out of MIT in 2011 with a commitment to bring sophisticated and innovated fabrication materials within the reach of engineers, designers and other creators all over the world.

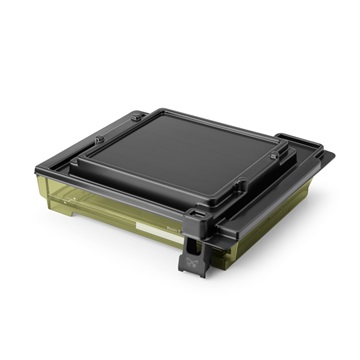

Form 3L Resin Tank

Low Force Stereolithography (LFS) 3D printing uses linear illumination and a flexible film tank to turn liquid resin into flawless parts. A key component of the LFS process, the strong dual-layer film at the bottom of the Form 3L Resin Tank allows for a dynamic and precise print process, scaled up for large format printing.

Call for pricing

Form 2 Resin Tank LT

Resin Tank LT is suited for long term use and rigorous, high volume printing, with a 2 to 5x longer lifetime depending on the material, more accurate printer detection, anti-spill geometry, and easier wiper release for streamlined workflows.

Call for pricing

Form 2 Clear Resin

Formlabs Clear resin polishes to near optical transparency, making it ideal for working with light or showcasing internal features. Supports print resolutions of 100, 50 and 25 microns.

Call for pricing

Formlabs Elastic 50A Resin Cartridge

Formlabs Elastic 50A Resin for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing. The “50A” in the name represents the material’s Shore durometer. If you need a more stiff flexible material, try Flexible 80A Resin.

Call for pricing

Form 2 Black Resin

Formlabs Black resin is formulated for models with very small features and intricate details. Supports print resolutions of 100, 50 and 25 microns.

Call for pricing

Form 2 White Resin

Formlabs White resin is formulated for models with very small features and intricate details. Supports print resolutions of 100, 50 and 25 microns.

Call for pricing

Form 2 Grey Resin

Formlabs Grey resin is formulated for models with very small features and intricate details. Supports print resolutions of 100, 50 and 25 microns.

Call for pricing

Form 2 Tough Resin

Formlabs Tough Resin was designed to simulate ABS plastic, with comparable tensile strength and modulus. Perfect for functional prototyping, this sturdy, shatter-resistant material has been developed to withstand high stress and strain.

Call for pricing

Filter by:

Clear All